BOOTH: Hall E4-026

Time: May 15th-19th

Add: China International Exhibition Center (Shunyi Hall), Beijing

Flute laminating machines are essential equipment in the corrugated packaging industry, used to bond single or double-faced corrugated boards with liners to create robust and durable packaging materials. These machines play a critical role in ensuring the structural integrity and aesthetic appeal of corrugated products. With various models available in the market, it is important to understand their differences to select the right machine for specific production needs. This article explores the common models of flute laminating machines and highlights their key distinctions.

Manual laminators are the most basic type, requiring operators to feed and align the corrugated boards and liners by hand. These machines are typically used in small-scale operations or for low-volume production.

1.1 Key Features:

Low initial investment cost.

Simple operation and maintenance.

Suitable for small businesses or custom orders.

1.2 Limitations:

Slower production speeds.

Higher labor dependency.

Limited precision in alignment and bonding.

Semi-automatic Flute Laminatorsmachines strike a balance between manual and fully automatic systems. They often include features like automatic glue application and partial alignment assistance but still require some manual intervention.

2.1 Key Features:

Moderate production speeds.

Reduced labor compared to manual machines.

Improved consistency in bonding quality.

2.2 Limitations:

Higher cost than manual machines.

Still requires some operator involvement.

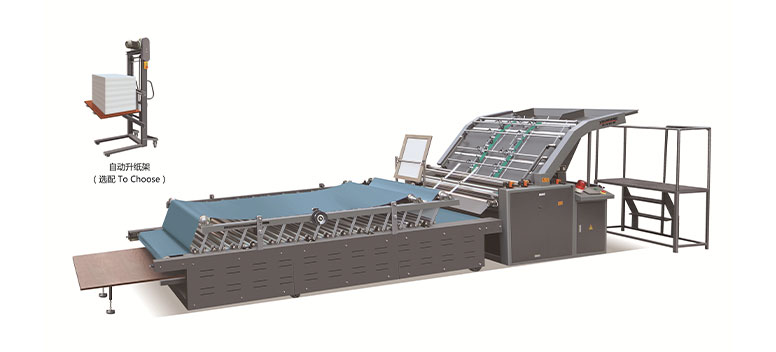

Fully automatic machines are designed for high-volume production and require minimal human intervention. They are equipped with advanced features like automatic feeding, glue application, alignment, and stacking.

3.1 Key Features:

High production speeds and efficiency.

Consistent and precise bonding quality.

Reduced labor costs and increased output.

3.2 Limitations:

Higher initial investment.

Requires skilled technicians for maintenance.

Digital laminators are the latest innovation in the industry, integrating digital controls and smart technology for enhanced precision and customization. These machines are ideal for high-end packaging solutions.

4.1 Key Features:

Advanced automation and control systems.

Customizable settings for different materials and designs.

Real-time monitoring and diagnostics.

4.2 Limitations:

Highest cost among all models.

Requires specialized training for operation.

1.Production Capacity

Manual and semi-automatic machines are suitable for low to medium production volumes, while fully automatic and digital laminators are designed for high-volume, continuous production.

2.Automation Level

Manual machines rely entirely on human operation, whereas fully automatic and digital models offer advanced automation, reducing labor requirements and improving efficiency.

3.Precision and Consistency

Fully automatic and digital laminators provide superior precision in alignment and bonding, ensuring consistent quality. Manual and semi-automatic machines may have variations due to human involvement.

4.Cost

Manual machines are the most affordable, while digital laminators are the most expensive due to their advanced features and capabilities.

5.Flexibility

Digital laminators offer the highest level of flexibility, allowing customization for different materials, designs, and production requirements. Manual and semi-automatic machines are less adaptable.

6.Maintenance and Skill Requirements

Fully automatic and digital machines require skilled technicians for maintenance and operation, whereas manual and semi-automatic machines are easier to maintain and operate.

Selecting the appropriate flute laminating machine depends on several factors, including production volume, budget, and specific packaging requirements.

Small Businesses: Manual or semi-automatic machines are ideal due to their lower cost and simplicity.

Medium to Large Enterprises: Fully automatic machines offer the best balance of speed, efficiency, and quality.

High-End Packaging Solutions: Digital laminators provide unmatched precision and customization for premium products.

Flute laminating machines are indispensable in the corrugated packaging industry, and understanding the differences between common models is crucial for making informed decisions. Whether you prioritize cost, production speed, or precision, there is a machine tailored to meet your needs. By evaluating your production requirements and budget, you can choose the right laminating machine to enhance your packaging operations and deliver high-quality products to your customers.

GET A QUOTE