BOOTH: Hall E4-026

Time: May 15th-19th

Add: China International Exhibition Center (Shunyi Hall), Beijing

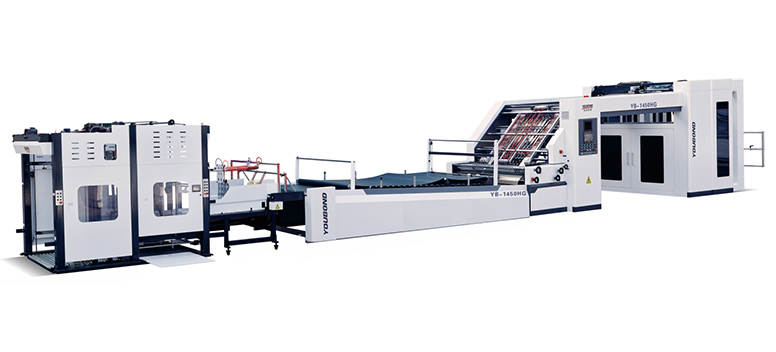

In the packaging and manufacturing fields, laminating cardboard can effectively enhance the strength, waterproofness and other properties of cardboard, thus being widely used. Then, what equipment is needed to laminate cardboard? Let's take a closer look.

This is the core equipment, which can be divided into different types according to the working mode and structure. The common ones include roller laminating machines. Through heating rollers and pressure rollers, they make the film and cardboard closely adhere under the combined action of heat and pressure. For example, in the packaging industry, when producing a large number of packaging cardboards, roller ;laminating machines can work efficiently, processing several meters of cardboard per minute. There are also flat laminating machines, which are suitable for small-batch and high-precision lamination tasks, such as making some special-sized display boards. They apply pressure to the cardboard and film through flat plates to complete the lamination.

In the lamination process, it is necessary to evenly transport the film onto the cardboard, and the film unwinding device undertakes this task. It can precisely control the unwinding speed of the film to ensure that the film does not wrinkle or break during the transportation process. A good unwinding device also has an automatic deviation correction function to ensure that the film can always be accurately attached to the cardboard, guaranteeing the lamination quality.

To ensure the smooth progress of lamination, it is necessary to stably convey the cardboard into the laminating machine. Common cardboard conveying equipment includes belt conveyors and chain conveyors. Belt conveyors drive the cardboard forward by friction, running smoothly and avoiding damage to the cardboard. Chain conveyors are suitable for transporting heavy cardboards. In large packaging enterprises, they can quickly transport stacks of cardboards to the designated positions, improving production efficiency.

After lamination, it is necessary to cut the cardboard into appropriate sizes, so cutting equipment is essential. Common ones include paper cutters and die-cutting machines. Paper cutters are easy to operate and can straight-cut large-format laminated cardboards according to the set sizes, being suitable for the processing of conventional-size cardboards. Die-cutting machines are more flexible. They can cut the cardboard into various shapes according to the pre-designed molds and are often used to make packaging boxes with special shape requirements.

1.Preheating Equipment: Before lamination, preheating the cardboard can make the film adhere to the cardboard better and improve the lamination effect. For example, for some thermoplastic films, the preheated cardboard can make the film melt faster and combine with the cardboard.

2.Cooling Equipment: The laminated cardboard has a relatively high temperature and needs to be cooled and shaped. The cooling equipment can speed up this process, shorten the production cycle and ensure the flatness of the cardboard.

3.Quality Inspection Equipment: To ensure the quality of laminated cardboards, quality inspection equipment is needed. For example, thickness detectors can detect whether the thickness of the laminated cardboard is uniform, and appearance detectors can check whether there are bubbles, delamination and other defects on the surface.

Laminating cardboard is a process that involves the coordinated operation of a variety of equipment. From the core function of the laminating machine to the film unwinding, cardboard conveying, cutting and various auxiliary equipment, each link is of great importance. Only by reasonably selecting and using these equipment can high-quality laminated cardboards be produced to meet the needs of different industries. If you have any other questions about cardboard lamination, such as the selection of different equipment brands, equipment maintenance, etc., you can further explore.

GET A QUOTE