BOOTH: Hall E4-026

Time: May 15th-19th

Add: China International Exhibition Center (Shunyi Hall), Beijing

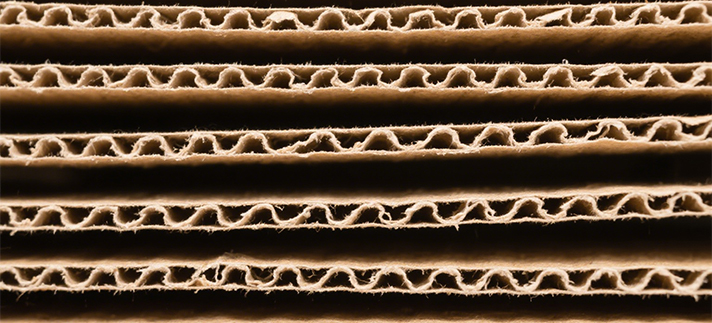

In the packaging industry, corrugated boards are widely used due to their durability, lightweight nature, and cost-effectiveness. A flute laminating machine plays a crucial role in manufacturing high-quality corrugated boards by bonding different layers of paper to create sturdy, multi-ply structures. This article explores what a flute laminating machine is, how it works, its key components, and its importance in the packaging sector.

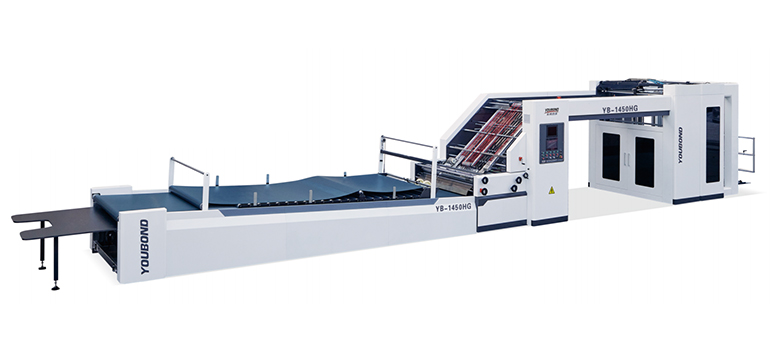

A flute laminating machine is a specialized industrial device designed to bond liner paper with fluted (corrugated) medium to produce single or double-faced corrugated boards. These machines ensure strong adhesion between layers, enhancing the structural integrity of the final product.

The flute laminating process involves several key steps:

1. Unwinding the Paper Rolls – The machine feeds liner paper and fluted medium from large rolls.

2. Heating and Glue Application – The fluted medium passes through a glue applicator, where adhesive is evenly applied.

3. Pressing and Bonding – The glued fluted medium is pressed against the liner paper under heat and pressure to ensure a strong bond.

4. Drying and Cooling – The laminated board moves through a drying section to solidify the adhesive before being cooled and cut.

1. Unwinding Stand – Holds and feeds paper rolls smoothly.

2. Preheating Section – Warms the paper for better glue absorption.

3. Glue Application Unit – Applies a uniform layer of adhesive to the fluted medium.

4. Pressure Rollers – Ensures firm bonding between layers.

5. Drying & Cooling Section – Removes moisture and stabilizes the board.

6. Slitting & Cutting Unit – Trims the laminated board to desired dimensions.

High Production Efficiency – Automates the lamination process, increasing output.

Consistent Quality – Ensures uniform adhesion and smooth surface finish.

Versatility – Can handle different flute profiles (A, B, C, E, F flutes).

Cost-Effective – Reduces material waste and labor costs.

V.Applications of Flute Laminated Boards

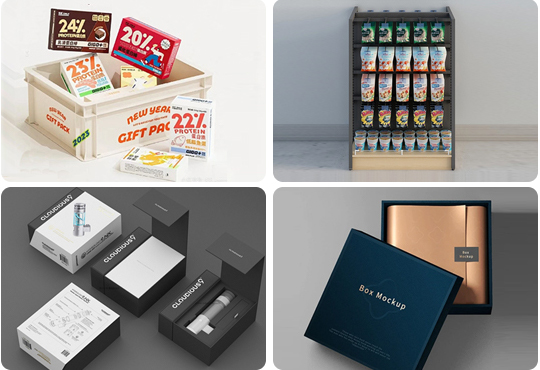

Packaging Boxes – Used in shipping, retail, and food packaging.

Displays & Signage – Provides lightweight yet rigid material for advertising.

Furniture & Interior Design – Used in eco-friendly furniture and partitions.

Conclusion

A flute laminating machine is an indispensable asset in the corrugated packaging industry, ensuring high-quality, durable, and lightweight boards for various applications. By automating the lamination process, manufacturers can achieve greater efficiency, consistency, and cost savings.

For businesses looking to enhance their packaging production, investing in a high-performance flute laminating machine is a smart move toward sustainable and efficient manufacturing.

GET A QUOTE