BOOTH: Hall E4-026

Time: May 15th-19th

Add: China International Exhibition Center (Shunyi Hall), Beijing

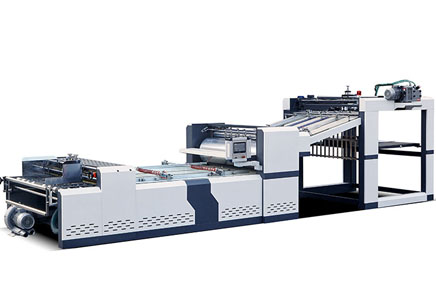

When choosing the right adhesive for Flute Laminating Machine, you should consider material compatibility, bond strength, curing time, water and heat resistance, environmental friendliness, cost, application technology and supplier support. Ensuring that the adhesive combines well with the material to be laminated and meets the end-product usage requirements improves productivity and product quality. By combining these factors, a more informed choice can be made.

Different materials, such as cardboard, plastic, and metal, each have distinct adhesive requirements. For example, water-based adhesives are typically ideal for paper and cardboard applications, while hot melt adhesives excel in rapid production settings, especially for plastics. It’s essential to confirm that the adhesive you choose can create a reliable bond with all types of materials being laminated.

Selecting an adhesive with the appropriate bonding strength is vital based on the intended use of the final product. Conducting bonding strength tests in actual application scenarios helps ensure that the chosen adhesive meets performance requirements, providing the durability necessary for the end product’s demands.

The curing time of the adhesive directly impacts production efficiency. Fast-curing adhesives can significantly reduce production cycles, allowing for quicker turnaround times. Conversely, slow-curing adhesives may be more suitable for applications that require adjustments over an extended period. It’s important to select an adhesive that aligns with the speed requirements of your production line.

For laminated products that will encounter humid or high-temperature environments, selecting an adhesive with strong water and heat resistance is critical. This choice ensures long-term stability and performance, preventing failures that could arise from exposure to adverse conditions.

As awareness of environmental issues grows, low VOC (volatile organic compounds) or solvent-free adhesives are increasingly preferred. These adhesives not only minimize the ecological footprint but also reduce health risks for operators, creating a safer workplace and aligning with sustainable practices.

Balancing cost with adhesive performance is essential. While high-performance adhesives may come with a higher price tag, the efficiency gains and quality improvements they offer can lead to significant savings in the long run. Evaluating the total cost of ownership versus upfront costs is key to making a smart investment.

Different adhesives may require specific application techniques, such as spraying, roller coating, or brushing. It’s crucial to ensure that the adhesive is compatible with your existing coating equipment, which helps achieve optimal application results and minimizes production disruptions.

Choosing a supplier that provides robust technical support can be a game changer. Suppliers with a strong focus on customer service can offer valuable professional advice on adhesive selection and application, as well as provide essential technical data and samples. This support helps you make a more informed choice, ensuring that the adhesive meets all your production needs effectively.

GET A QUOTE